Within the process industry there are constantly changing (extreme) conditions that present a challenge for the materials that must be able to withstand them. Materials must be able to resist high temperatures, corrosive and chemical attacks and wear from abrasive particles - as these conditions are becoming increasingly common.

Ceramic materials are very suitable for use in valve and control technology. They reduce the loss of production and therefore the additional costs.

|

BALL VALVE

Ceramic product: Ceramic ball and/or (valve) seat

BUTTERFLY VALVE

Ceramic product: Ceramic butterfly and/or ceramic liner in the valve

NON-RETURN VALVE

Ceramic product: Ceramic precision ball

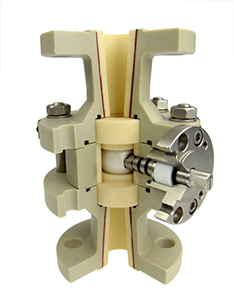

CHECK VALVE, CARTRIDGE

Ceramic product: Integrated ball and seat made of ceramicsCeramic parts of valves are a customer-specific product. Please contact our Engineering department for your application.

Think of applications like: