The field of application for ceramics is very broad. That's why our products can be found in a wide range of industries.

Machines and equipment often have to run longer and are subjected to heavier loads than for which they were designed. As a result, the service life of metal wear parts is getting shorter and shorter. The maintenance costs are getting higher, and especially unpredictable operations disturb the production process.

The use of ceramics for wear parts is an effective solution. the service life often increases from months to years.

In machines where many products are processed per unit time, ceramics can offer large advantages. For example in paper processing, textile machines, thread production and packaging machines.

Ceramics are also widely used in measuring and control equipment.

Applications | Materials

| Products

|

Many applications in mechatronics and semiconducting industry are not possible without ceramics. Examples are (the production of) LCD's, solar cells, optical components, lamps and IC's. The properties of ceramics are fully exploited in this application area. Especially the following combination of properties in one type of material is unique:

Ceramics can be processed down to micron level. high purity and accuracy are therefore central.

The use of ceramics within mechatronics and the semiconductor industry is very broad. Ceratec cooperates a lot with module and system builders.

Applications | Materials | Products

|

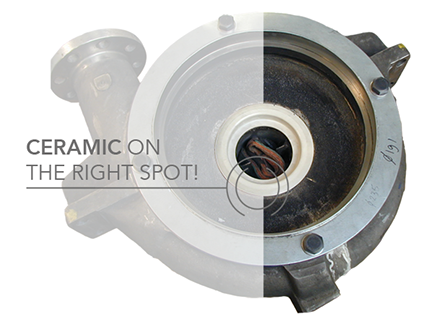

Ceramics are very popular in the pump industry. The individual properties of ceramics are all important, and together they give a unique combination - especially for those parts that come into direct contact with the medium to be pumped.

PROPERTIES OF CERAMICS:

Magnetically coupled pumps for abrasive, corrosive liquids do not operate without ceramic sliding bearings. Also pump housings, pump shafts, wear rings, high-pressure plungers, valves and bearings are made of ceramics.

Ceramics are used in all kinds of pumps: cooling water, dredging, chemicals, spinning, displacement, load pumps and mixers.

Applications | Materials | Products |

Did you know that there are more than 50 ceramic parts in an average car?

The most famous ceramic parts are the catalytic converter and the soot filter. Less well known - but no less important - are ceramic bearings, valves and balls. Ceramic components are also present in measuring and control equipment such as sensors.

Various ceramic tools are also used in the production of cars and trucks. Examples are:

Applications | Materials | Products |

Ceramics have been approved by the US Food & Drug Administration, and are therefore accepted as construction materials in these industries. The material is chemically inert, and can be found everywhere in food, beverage and pharmaceutics industries.

Examples are the production of baby food, candy, coffee and tobacco, and the processing of fish, meat, animal feed, cosmetics and medicine. The production machinery and control & analysis equipment also contain a lot of ceramic components.

Even in the final phase, in the packaging of the products, ceramics play a considerable role. The packaging is often done by using ceramic knives and parts.

Many industrial applications involve mixing, transporting, filling or dosing as process steps. Ceramic products are mainly applied because of their unique properties.

Applications | Materials | Products

|

Energy technology is often characterised by high temperatures or high electrical voltages. Temperature resistant and electrically insulating ceramics are then ideally suited as construction materials.

In conventional energy applications such as (nuclear) power stations and in engine and turbine construction you will find many ceramic components.

Ceramics are a durable and sustainable material - they last for a long time and play an important role in 'green' forms of energy generation. Ceramics are a popular material within the solar, wind and biomass sectors.

For cleaning processes such as water treatment, desulphurisation and waste water purification, ceramics are widely applicable.

Applications | Materials | Products |

Within chemistry, technical ceramics are often used due to the specific properties of the material.

Important properties in this industry:

Applications | Materials | Products

|

Ceramics find their way in many corners of the medical world. For example, there are ceramic components in X-ray equipment and MRI scanners. Ceramics also occur in dentistry; crowns and bridges are usually made of zirconium oxide, a relatively strong ceramic material.

Ceramic hip balls are used within surgery. these are common for hip joint prostheses.

Applications | Materials | Products

|

Ceramics are light and long-lasting high temperature resistant. These materials are often found in engines, for example as turbine components and coatings. Ceramic bearing components also exist in satellites. Inside measuring and control equipment, ceramics are very suitable for sensors and valves.

Applications | Materials | Products |

Ceramics are often used in the onshore and offshore, oil & gas and process industries.

Raw materials containing hard components and chemically corrosive raw materials place high demands on production and transport. These materials include minerals, catalysts, polymer powders, fertilizer half-finished products and pigments. But also for the production and transport of animal feed, food, concrete, stone, paper (pulp), glass and mining products, robust ceramics are well appreciated.

Important properties in this industry:

Applications | Materials | Products |