INDUSTRY

MATERIALS

APPLICATION

Ceramic precision balls are available in various materials and dimensions. Precision balls are used in a variety of applications, such as valves, ball bearings or measuring equipment.

Ceramics are resistant to many media and are hardly corroded. High hardness gives a high wear-resistance for many applications. The ball remains dimensionally stable for a long period of time, even under relatively high loads.

Ceratec can quickly deliver various precision balls from stock.

Call us for questions about our current stock.

|

|

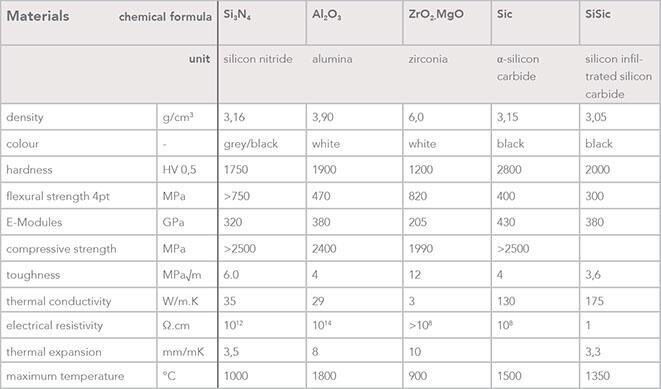

OVERVIEW OF MATERIALS AVAILABLE FOR LARGE CERAMIC PRECISION BALLS

In the semiconductor industry and other precision applications, there is an increasing need for precision bearings. Ceramics have many advantages as a construction material in bearings:

Ceramics are therefore used in the ball as well as the raceway.

DIAMETERS

Ceramic precision balls are available in diameters from 0.2 mm. The maximum available dimensions for silicon nitride, aluminum oxide and zirconium oxide are 100 mm. For sapphire and ruby, the available maximum size is 35 mm and 12.7 mm respectively.

TOLERANCES

As with precision balls made of other high-quality materials, ceramic precision balls are available in various qualities. The following table gives an overview of the qualities (according to AFBMA 1975 and ISO 3290).

Standard tolerance diameter ±0.25 microns, spherical ±0.25 microns and with a very smooth surface.