This unique material is as versatile as it is powerful, bringing us infinite opportunities to push boundaries.

Ours and yours.

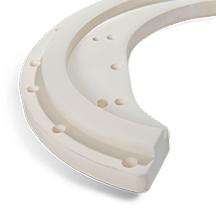

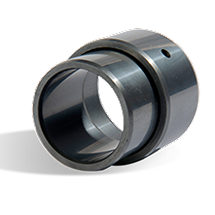

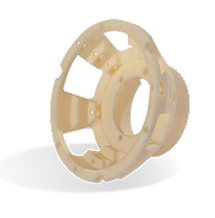

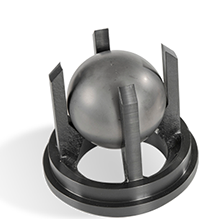

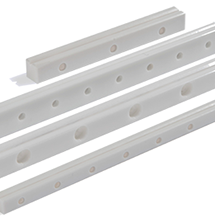

Technical ceramics enhance the functionality of your machine or device.

Like no other, we know which ceramic material is suitable where and when.

Ceratec Technical Ceramics has 35 years of experience in the application of technical ceramics. We offer you innovative solutions with a sustainable and durable material.

From the high-tech world to the aerospace industry: technical ceramics make a difference everywhere.

The properties of ceramics are very diverse. The circle diagram shows typical ceramic material properties. If your application requires at least two of these properties, then it may already make sense to use ceramics. If three of these properties are needed, then perhaps ceramics are the only option.

We work from prototype to series: small or large. Assemblies are also possible.

Ceratec is equipped with advanced production facilities to process technical ceramics. Besides conventional and CNC processing methods, we apply special joining techniques for complex products. We produce customer-specific products ranging from small numbers to large series.

Joeri

During the production process, quality checks are carried out continuously in our modern measuring room.

In order to check the quality of our materials and products, we have, among other things, the following measuring equipment at our disposal: