Technical-ceramic materials are well known for their extraordinary material properties. In order to be able to make optimal use of these properties, it is important to pay extra attention to the design of a component. A small change in the design can have a major impact on the manufacturability and service life. This is particularly the case when a ceramic component needs to be joined to another material.

The engineers at Ceratec have extensive knowledge of the wide range of ceramic materials available worldwide. In addition to this knowledge, each engineer has his/her own specialism within a certain industry. There are engineers specialized in high-tech precision engineering, and others are experts in designing hydrodynamic sliding bearings.

KNOWLEDGE

At Ceratec we have 35 years of experience with ceramic materials. We know the market worldwide, and of course we have a lot of experience with the application of these ceramic materials in the various markets.

RENDERS

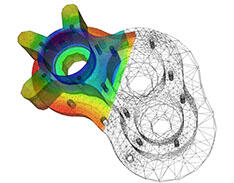

As with many technical applications, it helps in the engineering of ceramic materials and new products to clarify parts of the development process with renders, images and visualizations.Instead of just producing a part based on a drawing, the engineers at Ceratec can design a component or assembled product according to customer specifications.

At Ceratec, the 3D CAD package SolidWorks is used, including the FEM (Finite Element Method) module. This makes it possible to simulate components and assembled products, in order to guarantee the performance within the application in advance.

From “build to print” to “build to spec”

The main advantage of having an Engineering department combined with modern production facilities is that the entire process from technical challenge to prototype/series production and assembly can take place under one roof, so that the lines are short.