INDUSTRY

MATERIALS

APPLICATION

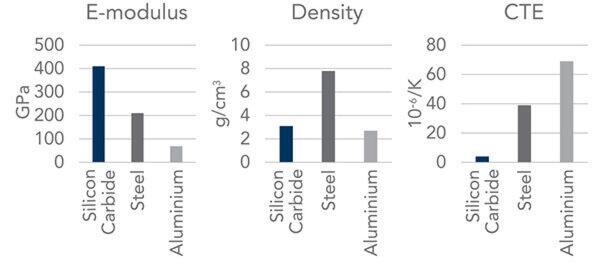

Structural parts made of silicon carbide (SiC) and aluminum oxide (Al2O3) have some major advantages over other common materials. The special properties of these ceramic materials are their high stiffness, low thermal expansion coefficient and low density. Moreover, these materials are non-magnetic and do not degas in vacuum applications. Due to this unique combination of properties, these materials are very suitable for extremely accurate machines in which special (process) conditions prevail.

|

|

BASE OF WAFER TABLE

Supporting structures, with the same thermal expansion as silicon, extremely accurate, wear-resistant, very high stiffness and lightweight.

HONEYCOMB STRUCTURE

Structures that are extremely lightweight and have high stiffness, especially intended for high temperatures or in ultra-high vacuum.

BAR FOR METROLOGY FRAME

Accurate positioning in machines and calibration tools. Low expansion and high stiffness play an important role here.

The combination of high modulus of elasticity and low thermal expansion coefficient is unique and makes this an excellent material for structural parts in high-tech systems. This combination of material properties ensures minimal mechanical deformation due to thermal influences. The combination of low density, high stiffness and low expansion coefficient - which is similar to that of silicon wafers - makes it an ideal supporting material for silicon wafers, picometer-scale metrology and other challenges within precision technology.

The added value of ceramics for structural parts is shown below by making a comparison with other common materials for structural parts.

Maximum dimensions in one piece up to 2300 mm.