INDUSTRY

MATERIALS

APPLICATION

Ceramic sliding bearings are very suitable for use under corrosive conditions or for liquids that contain sand or other abrasive particles. After all, ceramics are harder than sand and are highly resistant to most environments.

We are convinced that any pump manufacturer, designer or developer can take advantage of the benefits of ceramic bearings and their properties. When designing, these sliding bearings can help the designer build machines for applications that are difficult or impossible with traditional materials such as metals and plastics.

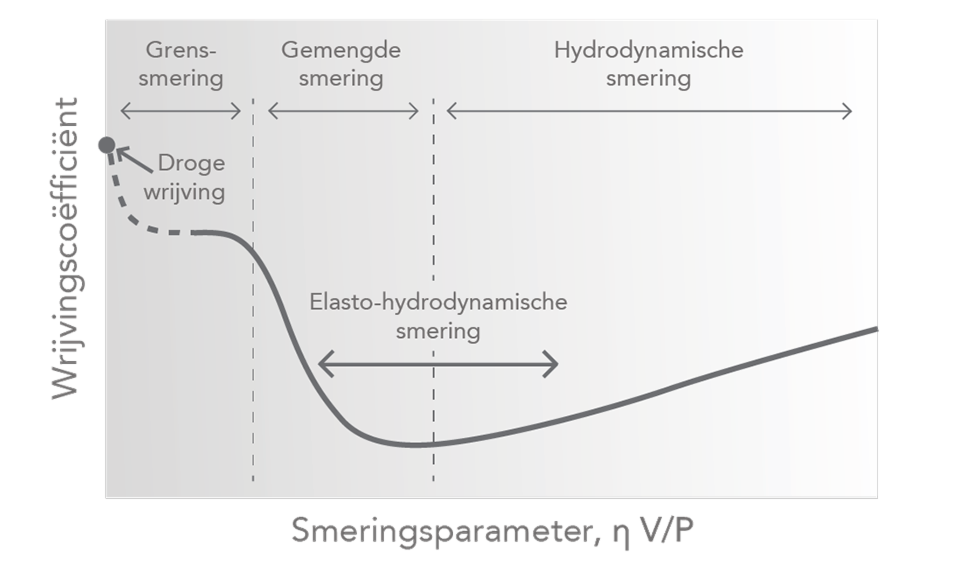

The pumped liquid, such as water or acid, provides lubrication.

With ceramics it is relatively easy to integrate a sliding bearing functionality into the structural part itself.

|

|

In all machines where a rotary movement is to be carried out, and where metals or plastics technically no longer satisfy, ceramic sliding bearings can be the solution.

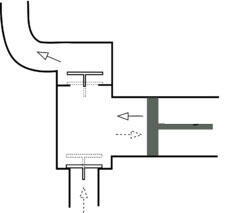

CENTRIFUGAL PUMP

Ceramic product: Medium-lubricated sliding bearings, i.e. the pumped medium provides the load-carrying capacity in the bearing construction. In this way an impeller can be loaded at the place where the forces arise: in the impeller itself

Advantages: Extremely long service life, resistant to abrasive particles, chemically inert, with very low friction and no need for seal packs.

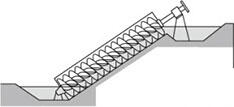

SCREW PUMP

Ceramic product: In addition to the bearings, the housing can also be made of ceramics or provided with a ceramic wear-resistant, inert, anti-wear coating. In this way, the service life is extended.

Advantages: Wear-resistant, chemically resistant and no metallic contamination due to wear and tear in the pumped product.

PLUNGER PUMP

Ceramic product: Ceramic plungers can tolerate much higher pressures than any metal or plastic, because the material is extremely pressure-resistant; 15,000 bars are possible. In addition, these plungers are highly wear-resistant against the sealing materials used.

Advantages: Wear-resistant and resistant to extremely high pressures.

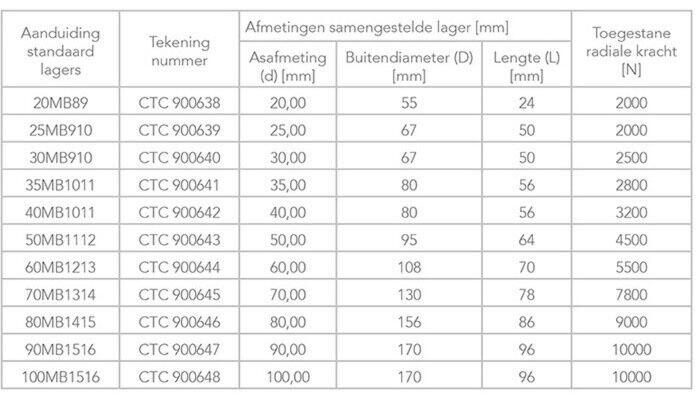

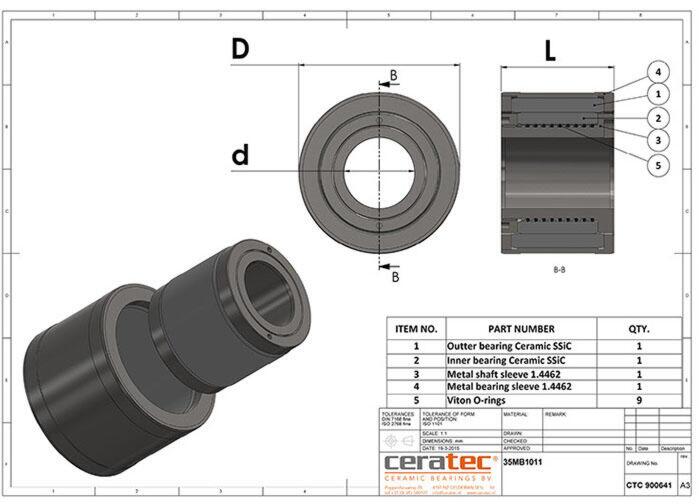

Ceramic sliding bearings can carry radial loads, as well as axial loads and all combinations of them. Structures can be used up to 400 ˚C, and the crucial ceramic components are protected by stainless steel construction elements.

Ceramics have added value when:

Maximum operating temperature for these bearings is 150 ˚C.

Optimal conditions for these bearings are: 3600 RPM (revolutions per minute) for model 20MB89 and 1200 RPM for model 100MB1516, temperatures below 100 ˚C, no misalignment, gradual starting, balanced radial load rotation.