INDUSTRY

MATERIALS

APPLICATION

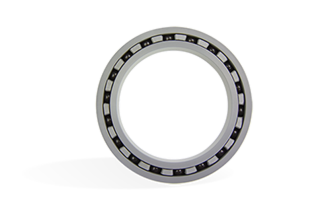

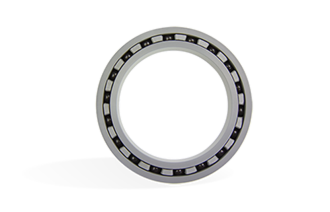

When a metal ball bearing reaches its technical limit, ceramic materials can often push these limits.

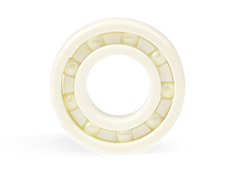

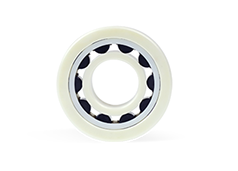

Ball bearings are available in either full ceramic or hybrid form. The emphasis is on application at higher temperatures and under corrosive conditions. Lubrication is usually less critical. At low loads and speeds, there is no need for lubrication at all.

The emphasis is on application at higher temperatures and under corrosive conditions.

If necessary, we can also develop and produce extremely accurate ceramic bearings at Ceratec.

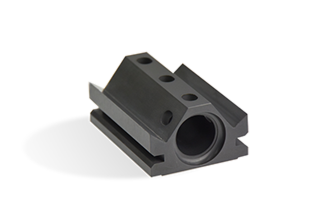

We can also integrate ball bearings into ceramic components by integrating raceways into the components themselves. This is more accurate and cost-effective than assembling multiple components.

|

|

If there are circumstances in which metal or plastic bearings are no longer an option, then we can offer added value with ceramic bearings.

Examples of environments where ceramic ball bearings have been used successfully:

SEAWATER

Ceramic product: Ceramic ball bearing / linear guide, ceramic raceways and balls, lubricated by seawater, possibilities for buoys, underwater robots.

Advantage: The service life of a mildly loaded bearing will be very long - up to infinity.

MEDICAL APPLICATION

Ceramic product: Ceramic roller bearing, ceramic raceways, ceramic balls.

ULTRA-HIGH VACUUM

Ceramic product: Roller bearings made entirely of ceramics.

MAGNETICALLY SENSITIVE ENVIRONMEN

Ceramic product: Ceramic roller bearings.

HIGH ACCELERATIONS

Ceramic product: Lightweight ball bearings.

LOW FRICTION

Ceramic product: Ceramic roller bearings.Ceramic ball bearings are developed according to customer specifications. Often the dimensions from the industry are common.

Contact us for your specific application, so that we can advise you on the choice of materials.