INDUSTRY

MATERIALS

APPLICATION

Ceratec has developed a zero point tooling system that can resist the highly abrasive environment inside a tooling machine for machining technical ceramics. Due to the very good wear-resistance and the high compressive strength, ceramics are pre-eminently suitable for this application.

|

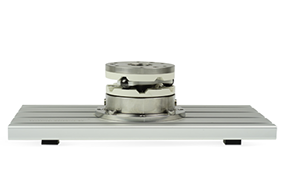

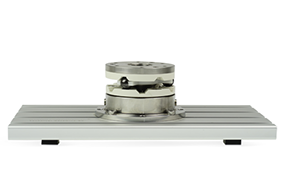

ZERO POINT TOOLING SYSTEM

The system consists of two parts: a chuck on the tooling machine, and a pallet on a workpiece holder. Due to the 2-micron repositioning accuracy of the pallet with respect to the chuck, a workpiece holder - with a workpiece inserted - can be exchanged simply and accurately between different tooling machines. Ceramic precision balls combined with ceramic V-grooves on both parts of the system are being used for the positioning.

Ceramic gear wheels are a customer-specific product. Please contact our business developers for your application.